Description

Sorbacal® SP is a high performance dry sorbent designed to provide compliance with the latest SO2, HCl, and HF emission regulations. This hydrated lime has been developed by the L’Hoist Group to increase the flexibility and effectiveness of the dry sorbent injection process. Due to its large specific surface area and high porous volume, Sorbacal® SP achieves superior pollutant removal while minimizing material usage and associated waste disposal costs.

Development

Involved the optimization of the hydration process which produced a product with superior physical characteristics that provides unmatched performance. Optimization of injection technique, flue gas temperature, waste recycle, and waste management have produced significant operating cost reductions.

| Standard hydrated Lime | Sorbacal® SP | |

|---|---|---|

| Purity (Content of Ca(OH)2) | > 90% | > 93% |

| BET Specific surface area | < 18 m2/g | < 40 m2/g |

| Total pore volume (0-1000 A) | < 0.10 cm3/g | < 0.20 cm3/g |

| d50 | 4-6 μm | 5-8 μm |

Results

The optimized hydration process yields a material that is physically much different than other hydrates on the market and this can be seen in the actual appearance of the product.

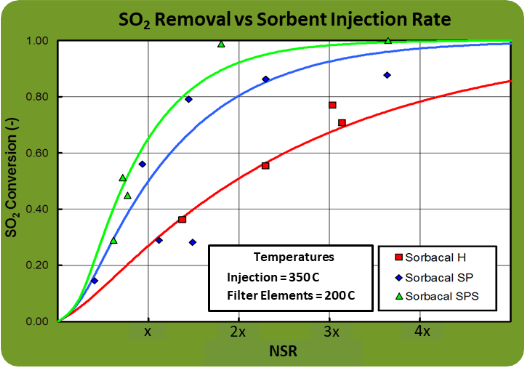

Application Example – SO2

- Control achieved through the use of dry sorbent injection prior to the ceramic filter.

- Solid waste is non-hazardous and has potential for commercial use. No water evaporated and no liquid waste generated. As shown in the graph below removals can be achieved in excess of 95%

Cost Savings through Optimization

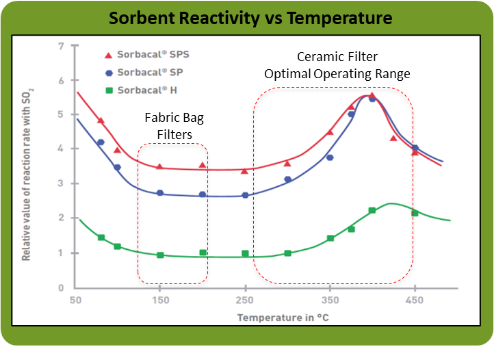

- The chart above shows the effects of flue gas temperature on sorbent performance.

- By combining sorbent usage with ceramic filter technology, the optimum operating temperature can be maintained.

- Technology optimization of this type will produce savings in operating costs in terms of less sorbent consumption and reduced waste generation.